What?

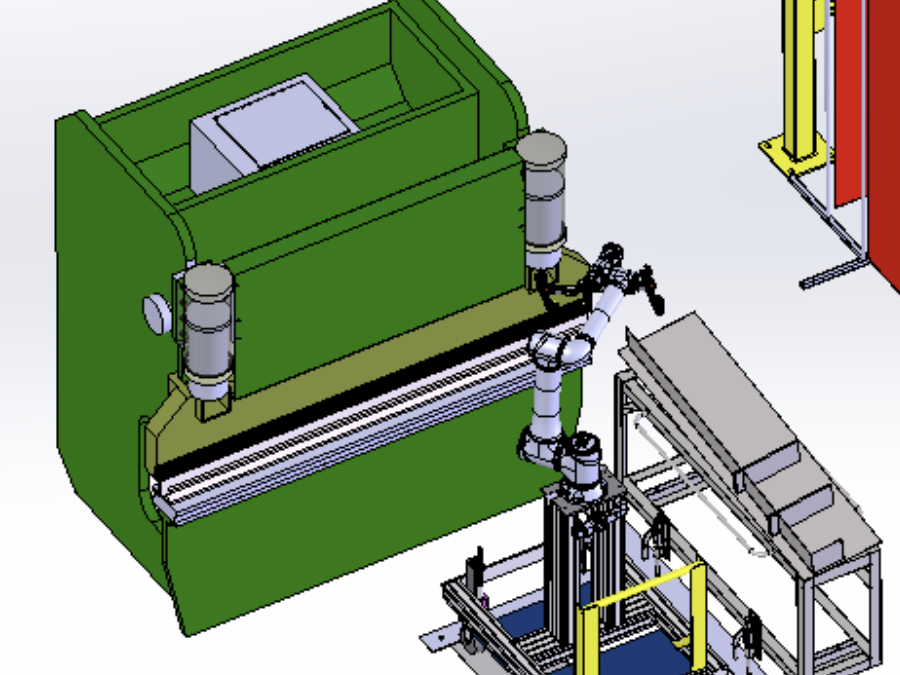

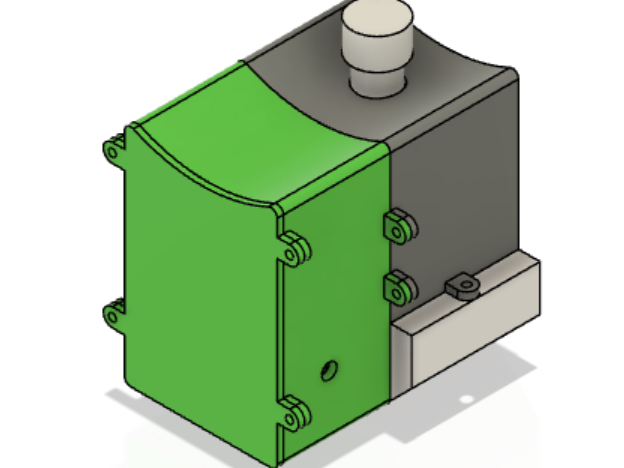

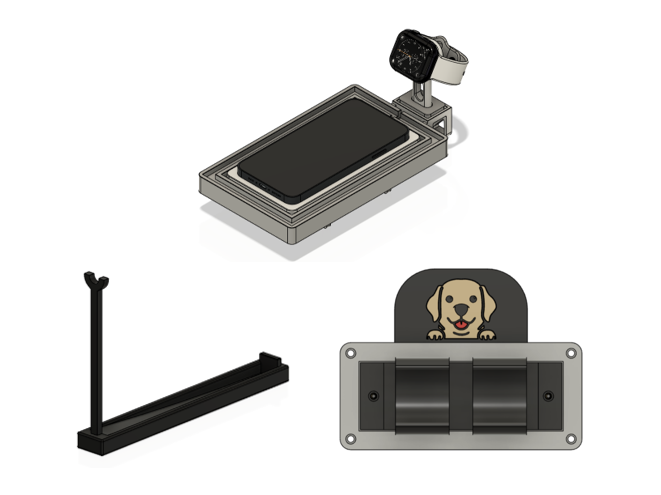

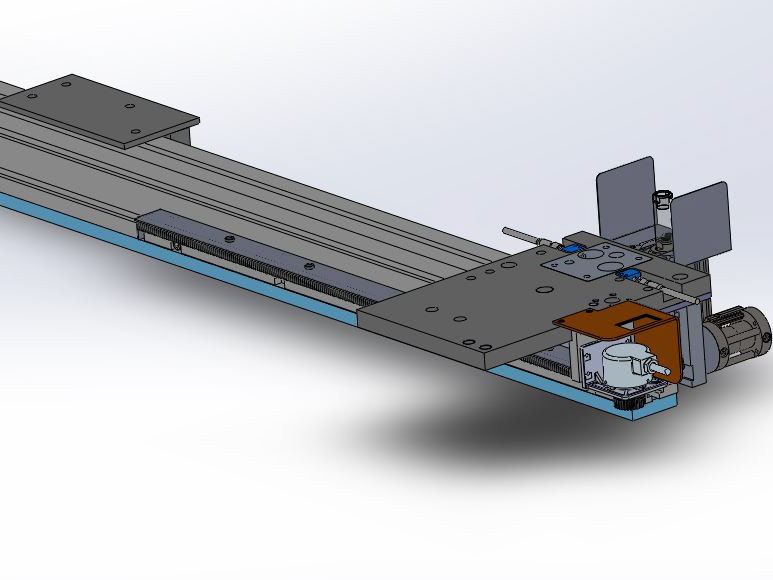

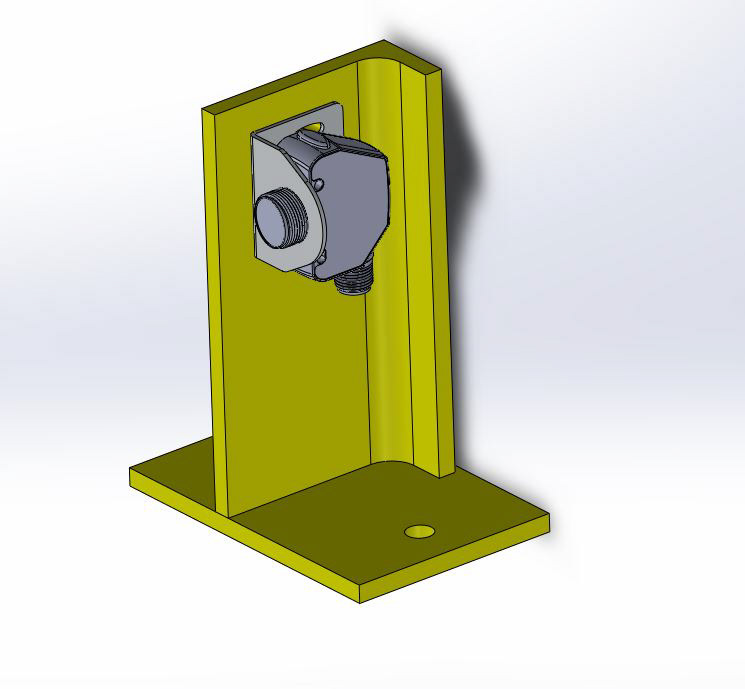

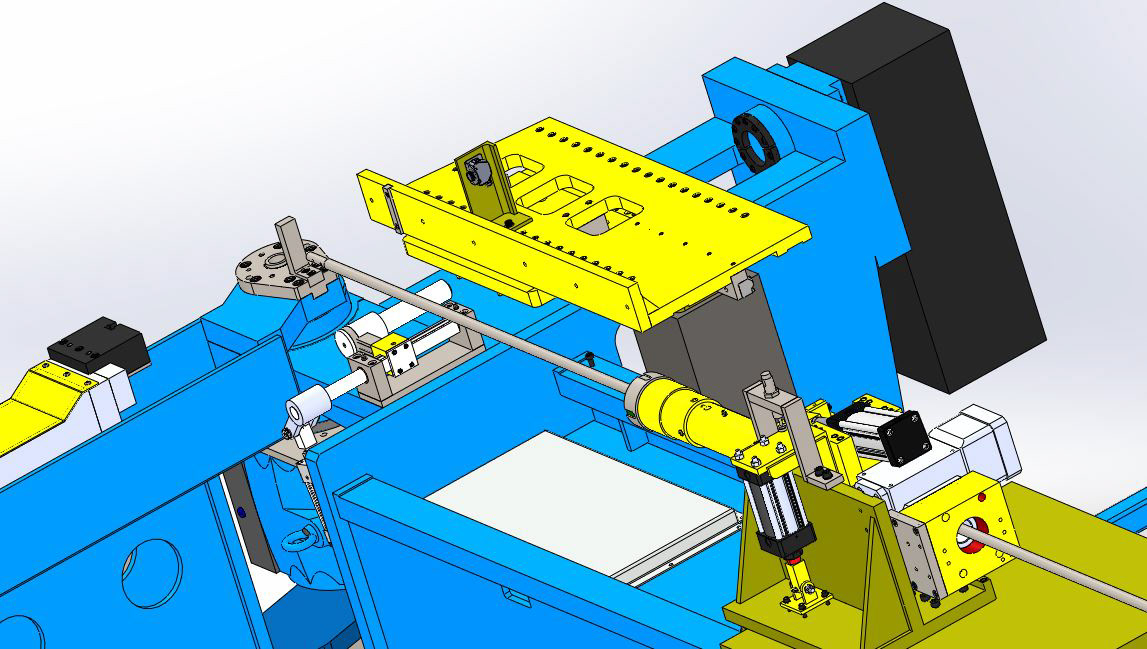

Designed a protective mounting bracket for a laser sensor, integrated a laser sensor into a Horn Tube Bender, and programmed the laser sensor to prevent the operator from starting a new tube bending cycle while a tube is still in the collet of the Horn Tube Bender.

How?

Used SolidWorks to design a protective mounting bracket, added parameters to optimize the design, and acknowledged DFA principles. Composed engineering drawings for the components designed to accommodate the machine shop for the purpose of manufacturing an accurate part.

Results?

Increased operator safety since the proximity sensor would prevent Horn Tube Bender from initiating a new tube bending process if a bent tube is present in the collet. Saved the company twenty-four thousand dollars by programming the sensor to send an I/O signal in order to initiate a new tube bending process.